Birdman1 goes DISCOVERY PRO- TEAM BLACK SHEEP

just started photo blogging, so this build is in full workflow as we speak, forgive me for now , this blog will change from hour to hour in the next coming days! thx for your understanding

The link list

TBS DISCOVERY PRO: http://team-blacksheep.com/products/prod:discopro

TBS ESC-MOTOR SET: http://team-blacksheep.com/products/prod:900kv_30aesc

TBS instruction/ hint page: TBS DISCOVERY PRO Installation Notes

the content of a TBS DISCOVERY PRO kit

My shopping list!

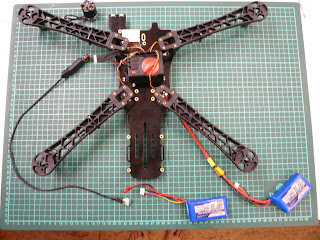

let's start building!

I start with the esc! standard layout

the Esc need some work before i gonna use them,

they are good but lets make them perfect!

and as you all know, no pain, no gain!!

they are good but lets make them perfect!

and as you all know, no pain, no gain!!

PICK YOUR COLOUR!

Mount 1 arm in the front and 1 in the back, now a extra note concerning the screws delivered with the package( sorry TBS) they are already way better then those delivered with the

STANDARD TBS DISCOVERY

but

they still are far off from the quality screws from DJI !

they fit ,okay, but there is a lot of play,

they are good for spots that you only access once. If you have some DJI screws laying around then use those in the final stage!!

STANDARD TBS DISCOVERY

but

they still are far off from the quality screws from DJI !

they fit ,okay, but there is a lot of play,

they are good for spots that you only access once. If you have some DJI screws laying around then use those in the final stage!!

Fix the esc like you would for real

fix 1 motor to the arm

check the wiring and how it will come in the (hopefully ) nearby future.

cut the servo wire ( jep really!!)

Cut the wiring to the correct lenght

Do the same with the servo cable

Repeat for the back

This is what you get,

Now make sure that you get a copy from each lenght

MY SOLDER TOOLS

solder the tips before you connect them to the print, then cut them to the correct lenght!

remove the old servo cable

and the brushless motor connection

remove the red / positive wire from the servo cable

solder them to the print! make sure that you make the correct connection (black on the side from black)

now solder back the brushless motor connection

now I was lucky, in checking all my connections I came to one that had a cold solder connection from UH, hmmmm.......

so make sure that you check yours ( by the way, I do this always)

it's clear what the cause is...... I was VERY lucky!!!!

PROTECT THE SOLDERPADS WITH LIQUID TAPE

aka PLASTIDIP

aka PLASTIDIP

New transparant crimpsock! FINALLY

they are now ready to be soldered to the

TBS DISCOVERY PRO FRAME

TBS DISCOVERY PRO FRAME

LAYOUT

FIRST BRING SOME TIN TO EACH SOLDERPAD

ATTENTION, MAKE SURE THAT YOU SOLDER THE WIRE'S INCLINATED INWARD's, why? later on you will be screwing those DJI arm's to the frame, if you solder straight forward your arm will push on those wire's, like that you have enough clearence!

number one

two

three

four, neeehn !!! Gotcha lol , first the powerconnection!!

four

Okay, I go for black

so I used dji screws for the obvious reason

this is a piece of neopreen 4mm thick

made 4 pieces from 5cm

this goes between the esc and the DJI arm, 2 advantages- anti slip and vibration absorber-

1 disadvantage- heat dissipation is less

nice and neat!!

connection cable between lower and upper plate

make sure that it is completely till the end

Preparation on the upper plate

NAZA V2 arrived

clean the plate

make sure that it is 100% straight and facing forward( motor connection)

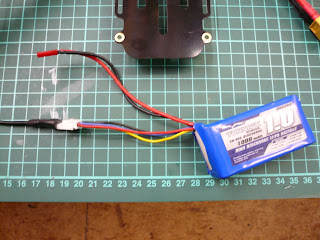

I use a servo tester to calibrate my esc's

This is my esc calibration setup, connect 1 motor , like that you can HEAR the beeps

connect the esc's (all of them) and set tester to maximum

connect power to tester

connect power to escbeep beep beep and set tester to zero, all done! esc's are calibrated

connect motors ANTI CLOCKWISE!!

this is just a test to show how LONG the plug is

+_ future possible possition from the batt

now we know that we can fix the ALU tube's

all 8 alu tubes

Led position, remember that little piece of sticky tape from the module

connection diagram

I need 4 standoff's

I placed the 4 standoff's around the naza module

now we can guide the cable's between the module and the standoff's

PMU preparation

servo plug from the PMU goes into X3

mainplug in the "exp"

this is a standard electrocopperplate with standard drilled 3 mm hole's .

more then enough clearence between the plate and the naze module

Now we have some room to play with + the copper functions like a extra shield!

cut the wire to the correct lenght

add some tin to the bottomplate solderpad

and solder them

your pick to block the copperplate, 3 mm nut or micro standoff

couble side tape +- 3 mm thinck ( we need some extra space below the PMU if we want to plug in a cable or so...

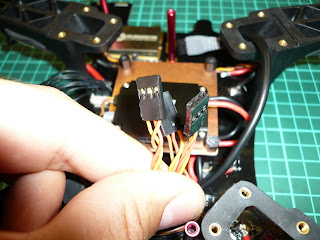

now, to be clear, I will be using the PPM SETUP WITH EZUHF

BUT

A LOT OF PEOPLE ASK ME ABOUT THE TRADITIONAL SETUP

SO HEREBY A BIG HINT TO CUT DOWN ON THE CABLE BOOM

Connection diagram for traditional receivers

A E T R U X1 X2 X3 STANDS FOR THE NAZA MODULE

1 2 3 4 5 6 7 8 IS FOR THE CONNECTION TO THE UPPERPLATE AND THATS ALSO HOW IT RUNS TO THE BACK

NOW TO CONNECT ALL OF THESE WE ONLY NEED 3 MALE TO MALE CROSSED SERVO CABLE'S

Cut away the nock and lip on both side's

so you have now 1 standard cable and 2 "cut" cable's

this is just a example on how the connection diagram will be

first we plug in the rudder connector ( 4 ) ( make sure that the signal side is on top)

now plug the connector that we just cut "HORIZONTAL" on the signal line --> orange on 1

now we do the same on the other side, orange this time on 5

so now we understand how the connection diagram work ,

copy it now to the module

attention: signal = bottom from the module

start on position 4= rudder

add the cut servo connector again in horizontal way,

orange to the outside

now the other plug, orange facing the rudder connector

so we have now 3 servoconnectors but 7 CONNECTION'S

Repeat the proces on the topplate

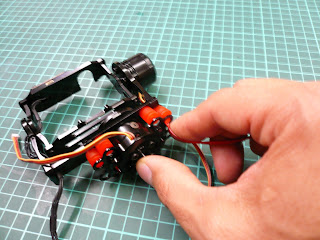

TBS DISCOVERY PRO BRUSHLESS GIMBALL ASSEMBLY

parts revealed

extra necessary parts

ATTENTION- concerning the use of loctite- All thought the gimball is a close as it can get to be ready it still needs some tweaking and tuning. in fact , you can use the gopro2 and gopro3 but you have to decide upfront which one it will be,

afterall the complete gimball is based and 360° balance.

SO ONLY USE LOCTITE WHERE I SHOW THE BOTTLE.

Later on you can put loctite when everything works flawlessly

Just unscrew one screw at the time, add the loctite, and put it back.

first step

front and back plate

make sure that you attach both in the correct direction

micromolex cable with 5 connections

plug it in the IMU, it's not easy, do it gentle!

guide the cable through the hole and bolt the IMU to the upperplate

this is how the casing goes together

fix the right arm( flat side inwards)

fix the left side ( again flat side inwards)

IMU PLATE goes on top

fold the micromolex cable as small as possible

guide it through the cnterhol from the left side

guide the bearing over the micromolex cable

put the 12mm screw in position

guide the arm over the cable and put it flat with the flange of the bearing, tie down the screw,

DO NOT OVERTIGHTEN!

DO NOT OVERTIGHTEN!

make 100% sure that the cable moves free, no rubbing or what so ever, then guide it through the hole from the arm and give it some play

fix the backplate to the left arm (the cable needs to go through the U hole

fix the right arm

pictures in hold